Safety implications of poor asset maintenance

Operating and maintaining assets effectively is key to managing costs and profitability. However, achieving it isn’t an easy feat. Asset-intensive industries are often operating in challenging environmental and economic conditions, from the world’s most remote locations at high altitudes or underground to managing the cyclical rollercoaster of commodity prices impacted by global pandemics. But when it comes to safety, there is a level of maturity, acceptance and awareness that has been reached industry-wide, regardless of operating conditions. Safety is at the forefront of decision-making and is intertwined in daily communications, risk analysis and activities.

Mitigating asset failures with Orien

When assets are poorly maintained, there is a lot at stake. At best, poor maintenance can lead to equipment failure resulting in downtime and loss of production. At worst, poor maintenance can compromise safety resulting in injury, fatalities, imprisonment for negligent personnel, environmental damage, loss of production, revenue, and reputation.

To mitigate the likelihood of asset failures and operate with safety at the forefront, it is important that the potential for failure and the consequences of those failures are understood for every asset and its’ components. While this may seem like a daunting task, built into Orien is a 9-step framework that can be easily followed:

- Identify components that are part of an asset

- Conduct a full criticality analysis using criticality matrix

- Identify the function of that component – why is the component there?

- Identify how the component’s function can fail

- Identify the consequence of the failure

- Identify how the component fails

- Identify the most efficient and cost-effective maintenance strategy, such as fixed time replacement or condition monitoring

- Lock in approved maintenance strategies complete with tasks, conditional comments and acceptable limits using rigid data governance to ensure that no uncontrolled changes are made and that there is an auditable trail of approved change history

- Plan, schedule and execute the agreed corrective actions

Following this framework allows for consistency in maintenance planning from asset to asset and ensures each asset and its components are examined with the same due diligence every time.

Tactics development in practice

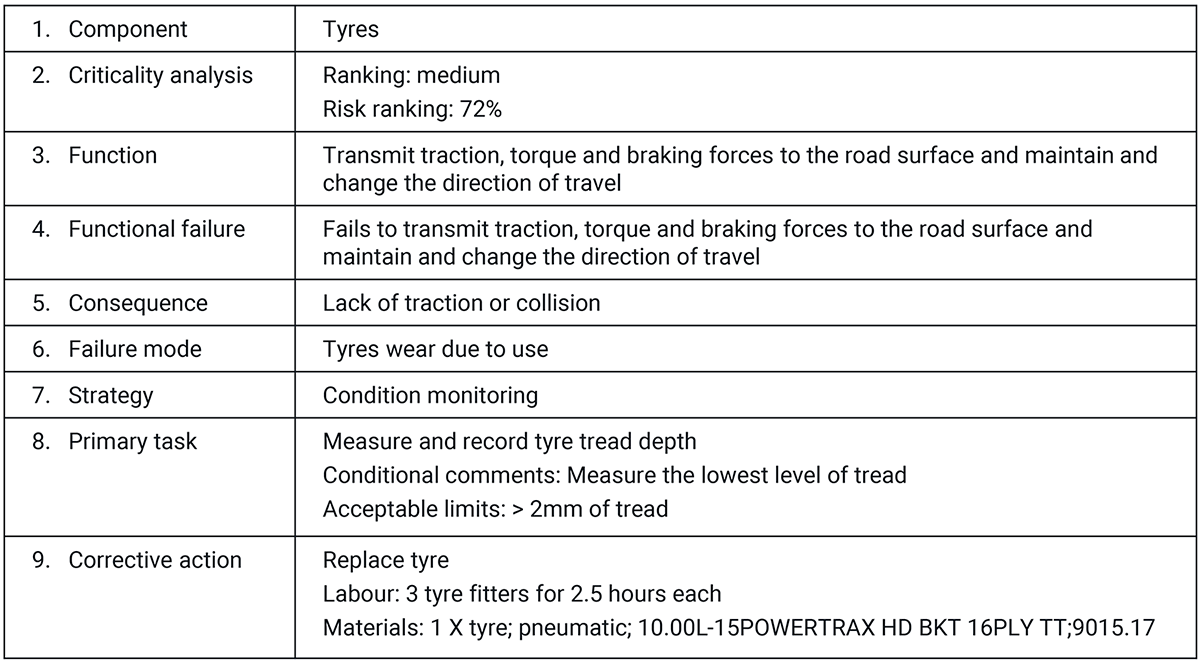

Orien is designed to develop end-to-end maintenance tactics at scale - for every component on every asset across an organisation. In this example, we follow the 9-step framework for a haul truck, focusing specifically on one component – the tyres. Comprehensive tactics development concludes with identifying corrective activities, complete with resources such as labour and materials. Corrective actions are triggered when primary inspection acceptable limits are exceeded. In this example, when tyre tread is less than 2mm, corrective actions are triggered to replace the tyre.

Designed by our in-house experts, this step-by-step framework has been used by our clients to build maintenance tactics for thousands of assets across global operations.

Safety in all that we do

Asset-intensive industries operate in some of the world’s most challenging conditions. One of our core values is ‘safety in all that we do’ - we developed Orien to enable organisations to maintain their assets effectively, reducing the likelihood of personnel injuries or worse resulting from poorly maintained assets.

Our team of experts are ready to help, reach out to us to learn more.

Our experience

Orien is a cloud-based asset management solution relied on by the world’s largest asset-intensive industries. Developed by Ausenco in collaboration with leading industry experts, Orien makes it easy to consolidate, collaborate on, and control maintenance strategies and budgets across your organization to keep assets working for you. Orien’s clients manage lifecycle costs and reduce uncertainty by understanding the critical activities that keep their operation running. With teams located worldwide and 24/7 support, Orien puts you on the path to better asset performance.